Junlebao’s World-Class Factory Crowned "Lighthouse Smart Factory" – Smart Manufacturing Empowers New Productive Forces in the Dairy Industry

2025/02/28 Reading:

Recently, six ministries and commissions including the Ministry of Industry and Information Technology and the National Development and Reform Commission jointly released the list of 2024 Lighthouse Smart Factories. With its "Dairy Industry Whole-Industrial-Chain Collaborative Smart Factory Project", Junlebao Dairy Group was successfully selected as a national benchmark enterprise, joining industry benchmarks across the board to demonstrate the hard power of China’s smart manufacturing. This selection marks another national honor for Junlebao in the field of smart manufacturing, and testifies to the authoritative recognition of its globally leading smart manufacturing system.

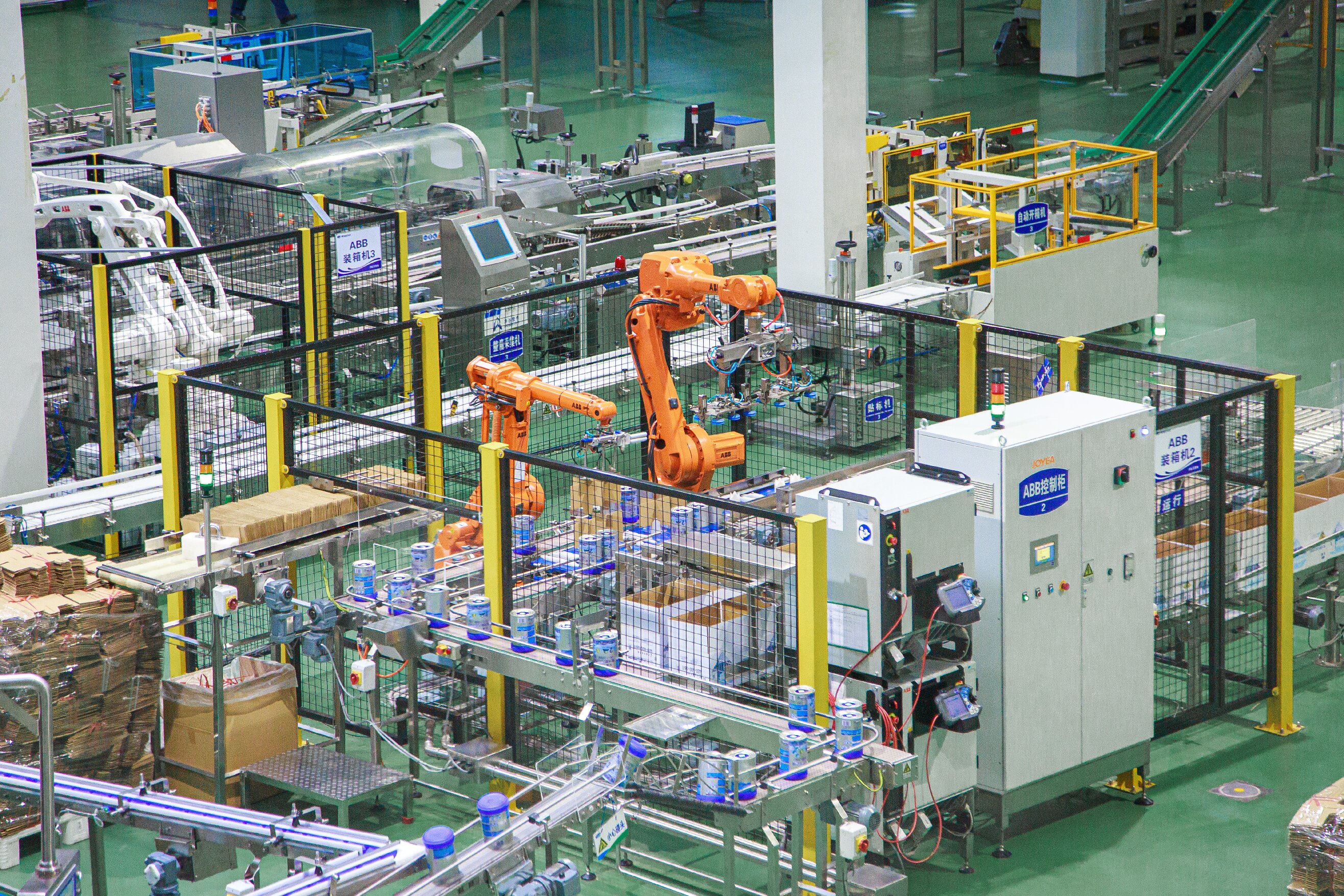

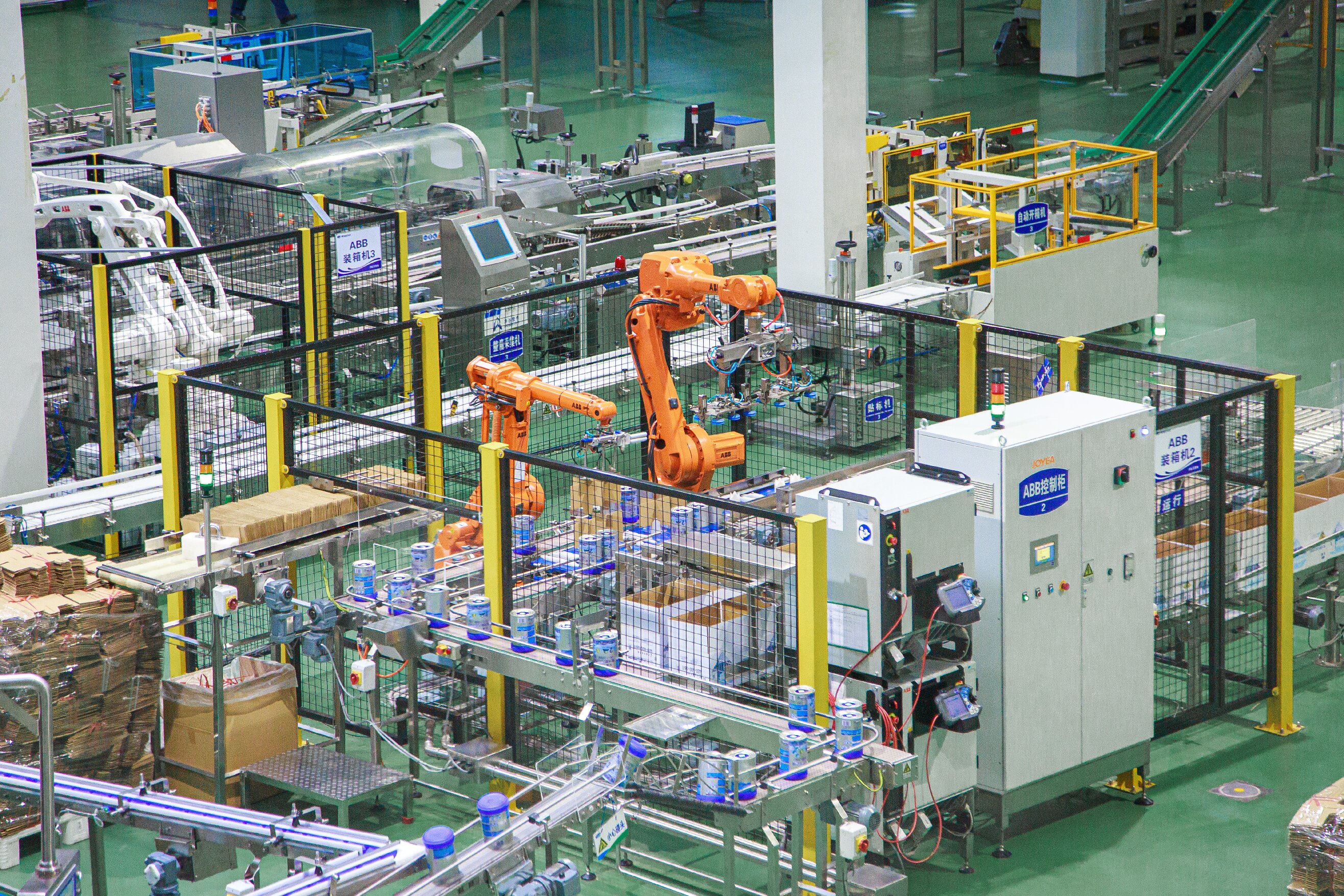

Rooted in the dairy industry and committed to continuous innovation, Junlebao has scientifically empowered the entire dairy industrial chain by building two core production and management models: the Integrated Whole-Industrial-Chain Model and the Six World-Class Model. Among these, the world-class leading factories under the Six World-Class Model integrate equipment and technical support from over 30 suppliers across more than 10 countries worldwide, boasting over 20 patents. They have built digital workshops and realized intelligent manufacturing, with top-level design adhering to the highest standards to ensure products are safer, more nutritious and purer.

Rooted in the dairy industry and committed to continuous innovation, Junlebao has scientifically empowered the entire dairy industrial chain by building two core production and management models: the Integrated Whole-Industrial-Chain Model and the Six World-Class Model. Among these, the world-class leading factories under the Six World-Class Model integrate equipment and technical support from over 30 suppliers across more than 10 countries worldwide, boasting over 20 patents. They have built digital workshops and realized intelligent manufacturing, with top-level design adhering to the highest standards to ensure products are safer, more nutritious and purer.

Junlebao has continuously increased investment in digitalization and intellectualization. By introducing advanced information technologies and automated equipment, and deeply integrating artificial intelligence, blockchain, 5G and other cutting-edge technologies, the Group has constructed a full-chain smart manufacturing system covering five key links: R&D, production, quality control, logistics, and energy and carbon management. This system drives the upgrading of the entire dairy industrial chain and helps foster new productive forces in the dairy sector.

In the pasture breeding link, relying on the industrial internet platform, Junlebao provides digital services such as environmental monitoring and precision feeding to small and medium-sized pastures, which has systematically improved the milk yield per cow of cooperative pastures. In the production link, intelligent production equipment and automated control systems have been adopted to realize unmanned operation, precise monitoring and efficient management throughout the production process. Through big data analysis and artificial intelligence technologies, the factories can real-time optimize production processes, improve production efficiency, and reduce energy consumption and costs.

In addition, Junlebao has built a smart supply chain system integrating 14 smart manufacturing scenarios including MES production management, APS intelligent scheduling and WMS intelligent warehousing. The numerical control rate of key equipment reaches 99.88% and the networking rate hits 99.78%. The full-life-cycle traceability system applying blockchain technology enables 100% accurate traceability of infant formula milk powder. Combined with machine vision inspection technology, the product qualification rate has maintained 100%, ensuring product quality and safety.

Junlebao’s smart manufacturing not only boosts the enterprise’s own operational efficiency, but also helps upstream and downstream enterprises achieve refined management through digital means, enhancing the competitiveness of the entire dairy industry ecosystem. In recent years, Junlebao has opened digital tools such as intelligent scheduling and equipment operation and maintenance to more than 4,600 enterprises in the industrial chain, realizing technology sharing. The Group has also taken the lead in formulating a number of national standards in the field of dairy smart manufacturing, filling the gap in industry norms for data interconnection.

Currently, the integrated innovation of digital and intelligent technologies has become the core driving force for the high-quality development of the dairy industry. Looking ahead, Junlebao will continue to focus on the forefront of digital and intelligent technologies, deeply empower the entire industrial chain, optimize all processes with smart technologies, provide higher-quality products for consumers, and contribute to the high-quality development of China’s dairy industry.

Junlebao has continuously increased investment in digitalization and intellectualization. By introducing advanced information technologies and automated equipment, and deeply integrating artificial intelligence, blockchain, 5G and other cutting-edge technologies, the Group has constructed a full-chain smart manufacturing system covering five key links: R&D, production, quality control, logistics, and energy and carbon management. This system drives the upgrading of the entire dairy industrial chain and helps foster new productive forces in the dairy sector.

In the pasture breeding link, relying on the industrial internet platform, Junlebao provides digital services such as environmental monitoring and precision feeding to small and medium-sized pastures, which has systematically improved the milk yield per cow of cooperative pastures. In the production link, intelligent production equipment and automated control systems have been adopted to realize unmanned operation, precise monitoring and efficient management throughout the production process. Through big data analysis and artificial intelligence technologies, the factories can real-time optimize production processes, improve production efficiency, and reduce energy consumption and costs.

In addition, Junlebao has built a smart supply chain system integrating 14 smart manufacturing scenarios including MES production management, APS intelligent scheduling and WMS intelligent warehousing. The numerical control rate of key equipment reaches 99.88% and the networking rate hits 99.78%. The full-life-cycle traceability system applying blockchain technology enables 100% accurate traceability of infant formula milk powder. Combined with machine vision inspection technology, the product qualification rate has maintained 100%, ensuring product quality and safety.

Junlebao’s smart manufacturing not only boosts the enterprise’s own operational efficiency, but also helps upstream and downstream enterprises achieve refined management through digital means, enhancing the competitiveness of the entire dairy industry ecosystem. In recent years, Junlebao has opened digital tools such as intelligent scheduling and equipment operation and maintenance to more than 4,600 enterprises in the industrial chain, realizing technology sharing. The Group has also taken the lead in formulating a number of national standards in the field of dairy smart manufacturing, filling the gap in industry norms for data interconnection.

Currently, the integrated innovation of digital and intelligent technologies has become the core driving force for the high-quality development of the dairy industry. Looking ahead, Junlebao will continue to focus on the forefront of digital and intelligent technologies, deeply empower the entire industrial chain, optimize all processes with smart technologies, provide higher-quality products for consumers, and contribute to the high-quality development of China’s dairy industry.